Resumen de especificaciones

-

Error de medición máx.

Caudal volumétrico:

±3 % lect. para DN 15

±2 % lect. para DN 25 a DN 200

±2 % lect. por encima de DN 200 -

Rango de medición

0 a 15 m/s (0 a 50 ft/s)

-

Rango de temperatura del medio

DN 15 a 65 (½ a 2½"): –40 a +150 °C (–40 a +302 °F)

DN 50 a 4.000 (2 a 160"): –40 a +170 °C (–40 a +338 °F) -

Máx. presión de proceso

N/A

Ámbito de aplicación

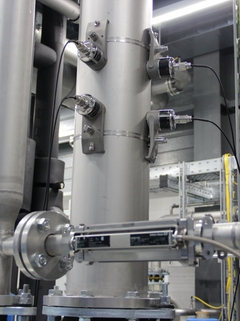

Prosonic Flow P 500 es el caudalímetro por ultrasonidos "clamp-on" ideal para garantizar una medición segura y sin mantenimiento de líquidos tanto conductivos como no conductivos, incluso en aplicaciones complejas. Mide el caudal de forma no invasiva y bidireccional, independientemente de la presión, la densidad y la conductividad, y sin interrumpir el proceso.

El FlowDC posibilita un montaje más flexible que nunca. La precisión especificada se mantiene con un tramo recto de entrada de tan solo 2 x DN, incluso en el caso de perfiles de flujo alterados.

Gracias a las juntas de acoplamiento especiales, este sistema "clamp-on" por ultrasonidos no necesita mantenimiento a lo largo de todo el ciclo de vida del producto.

Además, el Prosonic Flow P 500 está disponible con:

sensores para aplicaciones a altas temperatura para mediciones de hasta 550 °C (1.022 °F)

un paquete de aplicación Petroleum (PAP), que calcula el volumen estándar de hidrocarburos líquidos

Heartbeat Technology, que proporciona una transparencia continua de los procesos. De este modo, es posible detectar las adherencias antes de que afecten al funcionamiento

Ventajas

Montaje flexible: El FlowDC reduce al mínimo los tramos rectos de entrada

Estrictos estándares de seguridad: Prosonic El Flow P 500 se ha desarrollado conforme a los requisitos de seguridad funcional de la norma IEC 61508 y cuenta con homologaciones internacionales para zonas con peligro de explosión, Zona 1 y Clase I, División 1

Rendimiento de medición fiable: Los sensores contrastados, en combinación con el sistema de montaje sin mantenimiento, proporcionan señales estables a largo plazo, también en aplicaciones a altas temperaturas (≤550 °C / 1.022 °F)

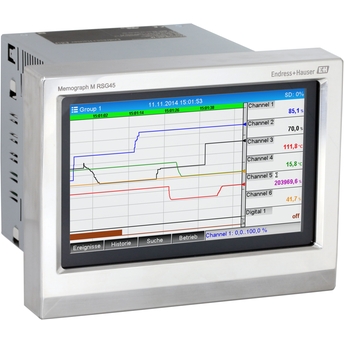

Un funcionamiento sencillo: El servidor web ofrece un acceso remoto completo, mientras que el indicador táctil del equipo permite interactuar cómodamente en campo

Información transparente sobre los procesos: Heartbeat Technology, con sus funciones integradas de diagnóstico, verificación y monitorización, garantiza el cumplimiento normativo y la seguridad de los procesos en todo momento

Baja inversión de capital: La rentabilidad aumenta con el diámetro de la tubería (hasta DN 4000/160")

Vídeos

Gama Extended

-

Productos de alta gama

- Altamente funcionales y prácticos

Excelencia técnica

Simplicidad

-

Productos estándar

- Seguros, resistentes y con poco mantenimiento

Excelencia técnica

Simplicidad

-

Productos de alta gama

- Altamente funcionales y prácticos

Excelencia técnica

Simplicidad

-

Productos especializados

- Diseñados para aplicaciones exigentes

Excelencia técnica

Simplicidad

Variable

| Gamas FLEX | Excelencia técnica | Simplicidad |

|---|---|---|

Gama Fundamental Satisfaga sus necesidades básicas de medición |

Excelencia técnica

|

Simplicidad

|

Gama Lean Maneje los principales procesos fácilmente |

Excelencia técnica

|

Simplicidad

|

Gama Extended Optimice sus procesos con tecnologías innovadoras |

Excelencia técnica

|

Simplicidad

|

Gama Xpert Domine las aplicaciones más exigentes |

Excelencia técnica

|

Simplicidad

Variable |

Loading alternative products

Loading alternative products

Predecesor

-

-

Información técnica (TI)

Proline Prosonic Flow P 500

Versión en español - 05/2021

Caudalímetro por ultrasonidos

EN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

6.8 MB

Nombre del archivo:

TI01504DES_0121.pdf

-

-

-

Información técnica (TI)

Proline Prosonic Flow P 500

Caudalímetro por ultrasonidos

EN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

6.8 MB

Nombre del archivo:

TI01504DES_0121.pdf

-

-

-

Manual de instrucciones (BA)

Proline Prosonic Flow P 500

Caudalímetro por ultrasonidos basado en el tiempo de vuelo

HARTEN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

9.5 MB

Nombre del archivo:

BA02025DES_0121.pdf

-

-

-

Manual de instrucciones (BA)

Proline Prosonic Flow P 500

Caudalímetro por ultrasonidos basado en el tiempo de vuelo

Modbus RS485EN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

8.6 MB

Nombre del archivo:

BA02026DES_0121.pdf

-

-

-

Parámetro del equipo (GP)

GP Proline Prosonic Flow P 500

Ultrasonic time-of-flight flowmeter

HARTEN ES 31/01/202410/05/2021Idioma:

Inglés

Versión:

31/01/2024

Tamaño del archivo:

2.4 MB

Nombre del archivo:

GP01147DEN_0224-00.pdf

-

-

-

Parámetro del equipo (GP)

GP Proline Prosonic Flow P 500

Ultrasonic time-of-flight flowmeter

Modbus RS485EN ES 31/01/202410/05/2021Idioma:

Inglés

Versión:

31/01/2024

Tamaño del archivo:

2.9 MB

Nombre del archivo:

GP01148DEN_0224-00.pdf

-

-

-

Instrucciones breves (KA)

Proline 500

Transmisor con sensor ultrasónico de tiempo de vuelo

Modbus RS485EN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

2.4 MB

Nombre del archivo:

KA01476DES_0121.pdf

-

-

-

Instrucciones breves (KA)

Proline Prosonic Flow P

Sensor ultrasónico de tiempo de vuelo

EN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

1.7 MB

Nombre del archivo:

KA01474DES_0121.pdf

-

-

-

Instrucciones breves (KA)

Proline 500

Transmisor con sensor por ultrasonidos basado en el tiempo de vuelo

HARTEN ES 31/01/202410/05/2021Idioma:

Español

Versión:

10/05/2021

Tamaño del archivo:

2.3 MB

Nombre del archivo:

KA01475DES_0121.pdf

-

-

-

Instrucciones de instalación (EA)

Replacing the transmitter

Prosonic Flow 500

EN ES 01/08/2021Idioma:

Inglés

Versión:

01/08/2021

Tamaño del archivo:

819.1 KB

Nombre del archivo:

EA01335DA2_0121.pdf

-

-

-

Instrucciones de instalación (EA)

EA Replacing the sensor, sensor holder, Installation set

Prosonic Flow P 500, I, W 400

EN ES 01/03/202415/12/202101/08/2021Idioma:

Inglés

Versión:

01/03/2024

Tamaño del archivo:

1.4 MB

Nombre del archivo:

EA01368DA2_0323-00.pdf

-